The Future of Industrial Automation

In today’s industrial landscape, where network efficiency and reliability are paramount, Ethernet APL (Advanced Physical Layer) is becoming increasingly significant. Ethernet-APL represents a major advancement in the evolution of Ethernet technologies tailored for industrial environments. As a variant of Single Pair Ethernet (SPE), it greatly simplifies and enhances physical data transmission within networks — enabling both data communication and power supply over a single twisted pair.

This article explores the key features of Ethernet APL, its advantages, and its potential impact on the industrial sector, as well as INSOL’s product line that supports this innovative technology.

This article explores the key features of Ethernet APL, its advantages, and its potential impact on the industrial sector, as well as INSOL’s product line that supports this innovative technology.

What is Ethernet APL?

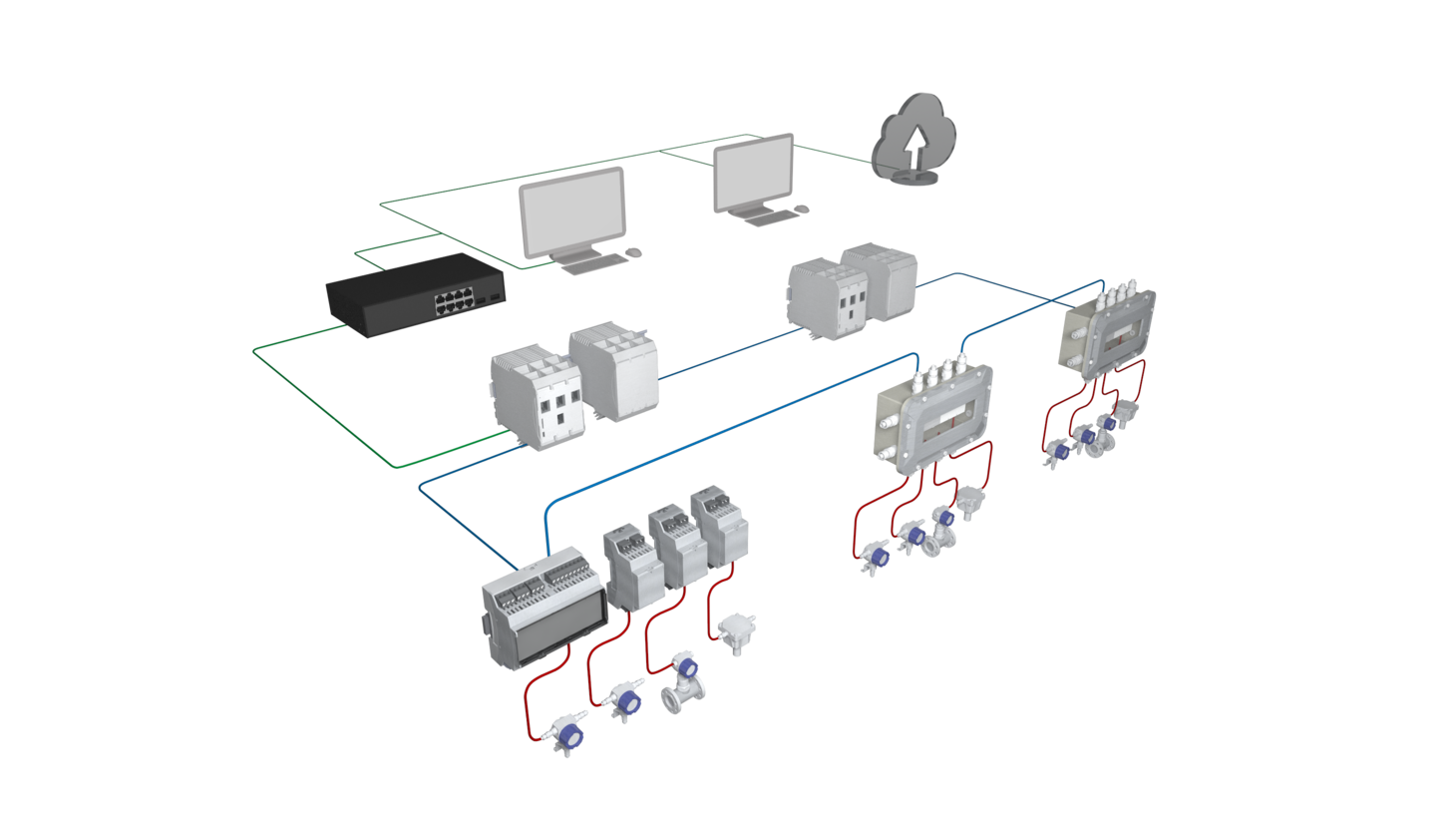

Ethernet-APL is a reliable and efficient two-wire Ethernet physical layer based on the 10BASE-T1L standard, designed for deployment in harsh industrial environments and hazardous (explosive) areas of process facilities. It enables direct connection of field devices to Ethernet-based systems, while the use of a switched network architecture eliminates unwanted interference between devices connected to the same network.

Ethernet-APL incorporates technologies and design options that are well-established in process automation. These include the proven “trunk-and-spur” topology, which allows for the simultaneous transmission of power and data to field instrumentation and devices.

Ethernet-APL incorporates technologies and design options that are well-established in process automation. These include the proven “trunk-and-spur” topology, which allows for the simultaneous transmission of power and data to field instrumentation and devices.

Extended Reach

Support for Power over Data Line (PoDL)

Data Transmission Speed

One of the key advantages of Ethernet APL is its ability to transmit data over distances of up to 1000–1500 meters — significantly surpassing the limitations of standard 100Base-T Ethernet. This extended range reduces the need for intermediate devices and gateways, resulting in substantially lower infrastructure and maintenance costs.

Ethernet APL supports Power over Data Line (PoDL) technology, enabling simultaneous transmission of data and electrical power over a single pair of wires. This simplifies the deployment of field instruments and networked devices by eliminating the need for a separate power infrastructure.

Ethernet APL delivers data rates of up to 10 Mbps, which is more than sufficient for most field-level applications such as real-time monitoring and process control.

Advantages of Ethernet APL

Use in Hazardous Areas

Integration with IIoT

Advancing Industrial Control Systems

Who Needs Ethernet APL?

Ethernet APL supports the development of next-generation architectures, such as NAMUR Open Architecture (NOA) and the Open Process Automation Standard (O-PAS™). As such, the technology delivers clear benefits to a wide range of users and stakeholders.

Ethernet APL devices and networks are easily integrated into Industrial Internet of Things (IIoT) environments. This allows companies to implement intelligent data monitoring and process control systems based on real-time information from the field.

Ethernet APL equipment is certified for use in hazardous areas (Zones 0, 1, and 2). This enables the integration of Ethernet-based solutions in industries such as chemical processing, oil & gas, and others where explosion protection requirements are critical.

Ethernet APL networks can be deployed by:

► Industrial enterprises and their operators

► IControl system vendors

► IEquipment suppliers and system integrators

► IManufacturers of field instrumentation and network-enabled devices

► Industrial enterprises and their operators

► IControl system vendors

► IEquipment suppliers and system integrators

► IManufacturers of field instrumentation and network-enabled devices

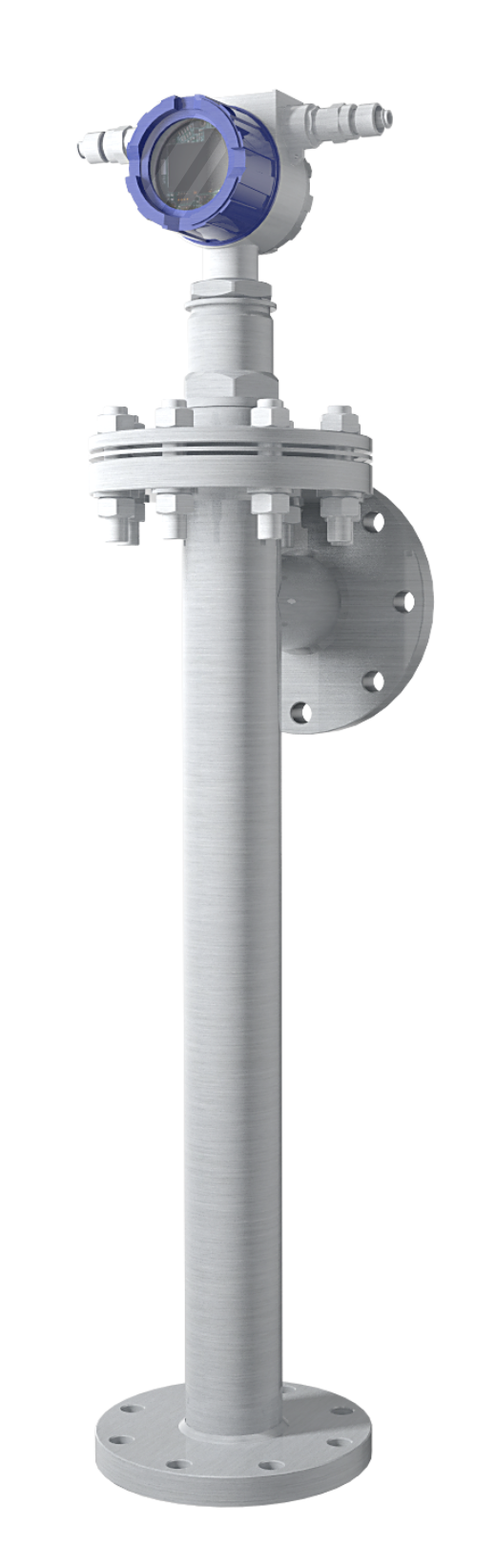

INSOL 901, 902

Provides accurate measurement of multiple phase levels in tanks and process vessels. Equipped with built-in Web and FTP servers for remote configuration and data access.

INSOL 903

Designed to measure water content in oil and other liquids. Also features integrated Web and FTP servers, enabling real-time monitoring and diagnostics.

MC30 и MC31

Network devices that convert between 10Base-T1L and 100Base-T interfaces for seamless integration into upper-level control systems. Support power transmission from PoE switches (Power over Ethernet).

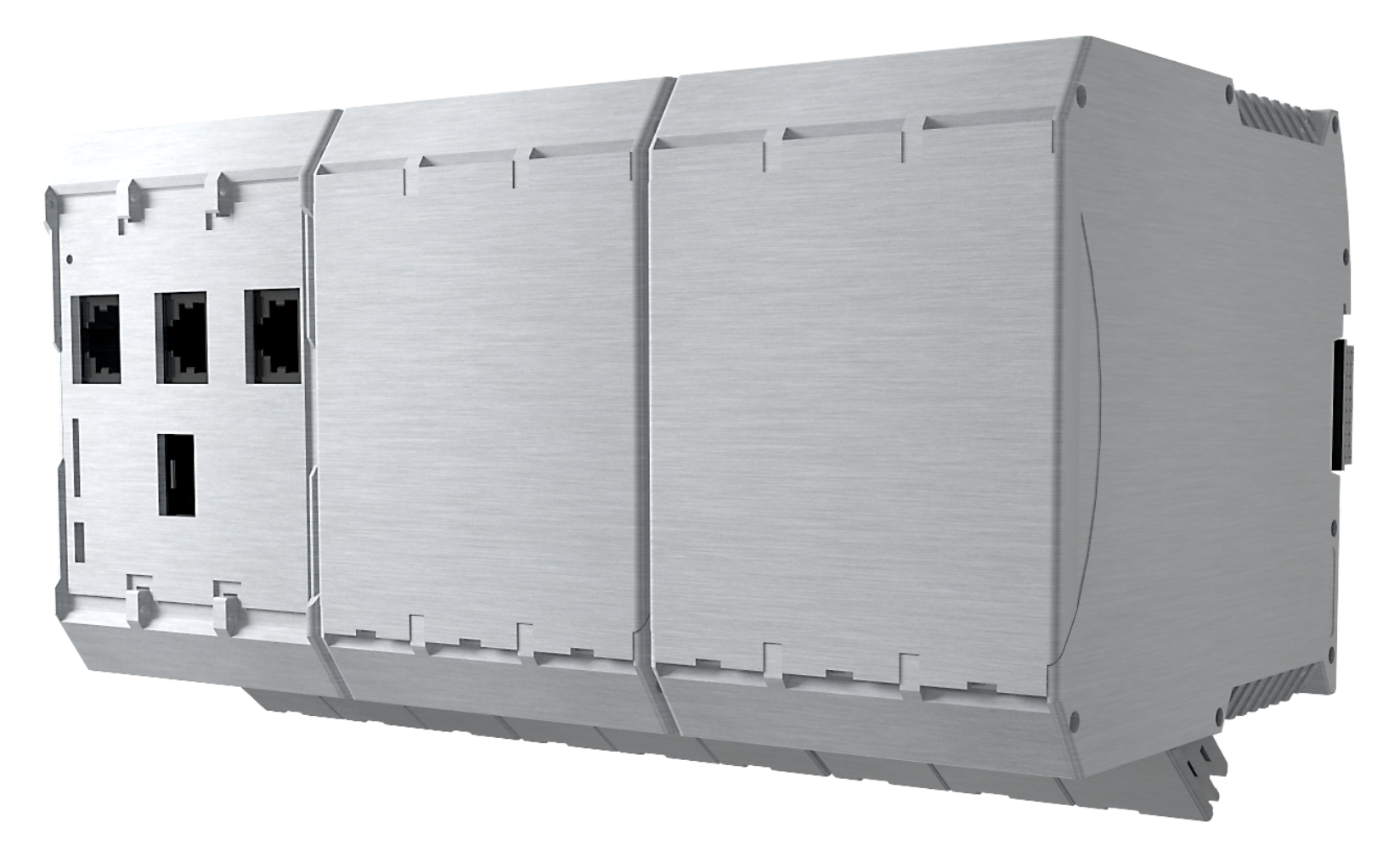

INSOL NODE

Available in programmable and non-programmable versions, these rugged switches support the 10Base-T1L Ethernet protocol and are used to connect field devices into a unified Ethernet APL industrial network.

INSOL Products Supporting Ethernet APL

Inline Moisture Analyzer

Media Converters

Industrial Ethernet Switch

Enable scalable, modular integration within Ethernet APL networks.

INSOL 100X EM

Compact modules for flexible integration into distributed automation systems.

INSOL 1000 NCU

Multiphase Level Transmitter

Benefits of Using INSOL Products with Ethernet APL

► Simplified Infrastructure. With support for PoDL and 10Base-T1L, INSOL devices significantly reduce cabling and auxiliary equipment requirements, streamlining the overall infrastructure.

► High Reliability and Accuracy. INSOL instruments deliver dependable and precise performance, even under demanding operating conditions.

► Compatibility and Flexibility. INSOL devices are easily configurable and integrate seamlessly with existing field systems, offering flexibility in deployment and use.

► Remote Configuration and Maintenance. Devices support remote diagnostics and configuration over the network, enabling efficient maintenance and reduced on-site interventions.

► High Reliability and Accuracy. INSOL instruments deliver dependable and precise performance, even under demanding operating conditions.

► Compatibility and Flexibility. INSOL devices are easily configurable and integrate seamlessly with existing field systems, offering flexibility in deployment and use.

► Remote Configuration and Maintenance. Devices support remote diagnostics and configuration over the network, enabling efficient maintenance and reduced on-site interventions.

Advantages of INSOL Instruments

High Accuracy and Reliability

Unique Features and Capabilities

Innovative Technologies

Versatile Connectivity

INSOL actively incorporates advanced technologies and communication protocols into its product development, including smart instrumentation and seamless integration with Industrial Internet of Things (IIoT) platforms. This ensures full digital integration of instruments into local and enterprise-level control systems.

INSOL offers measurement instruments with distinctive functional capabilities. These features significantly enhance process transparency and enable automation of corrective actions when deviations occur — not only detecting anomalies but also predicting potential process disruptions in advance.

INSOL instruments are known for their exceptional measurement accuracy and operational reliability, ensuring continuous monitoring of critical process parameters. This contributes to safe, uninterrupted operation of industrial units and minimizes the risk of deviations from technological regimes.

INSOL instruments support a variety of communication protocols, allowing easy integration into virtually any control system, regardless of vendor or infrastructure.

Driving Innovation and Digital Transformation with INSOL and Ethernet APL

The INSOL Group continues to evolve its product line, introducing innovations and adapting to new market challenges and demands. INSOL’s precision instruments help industrial enterprises reach new levels of efficiency and quality control, supporting sustainable development and long-term competitive advantage.

Ethernet APL plays a pivotal role in accelerating the large-scale digitalization of production processes. With its ability to deliver high performance and reliability in the most demanding environments, Ethernet APL opens new horizons for the advancement of industrial automation and the creation of intelligent manufacturing systems.

By implementing Ethernet APL, companies can significantly enhance operational efficiency, reduce costs, and strengthen their competitiveness in the global industrial landscape.

By implementing Ethernet APL, companies can significantly enhance operational efficiency, reduce costs, and strengthen their competitiveness in the global industrial landscape.